REBHAN Decoration

Establishing your brand on the global market requires a holistic concept. Your packaging forms an integral part of your brand image and must reflect and support your brand promise and brand value. It is the eye-catcher, the first thing your customers see. On shop shelves and online, the look needs to arouse curiosity and provide an essential purchase incentive. It needs to be like love at first sight!

A brand’s recognition value is also vital. Irrespective of which individual product in your line you are placing on the market, the look and styling must clearly represent the brand character. Customers that you have already attracted and retained to your brand should be able to instantly “recognise” each new product.

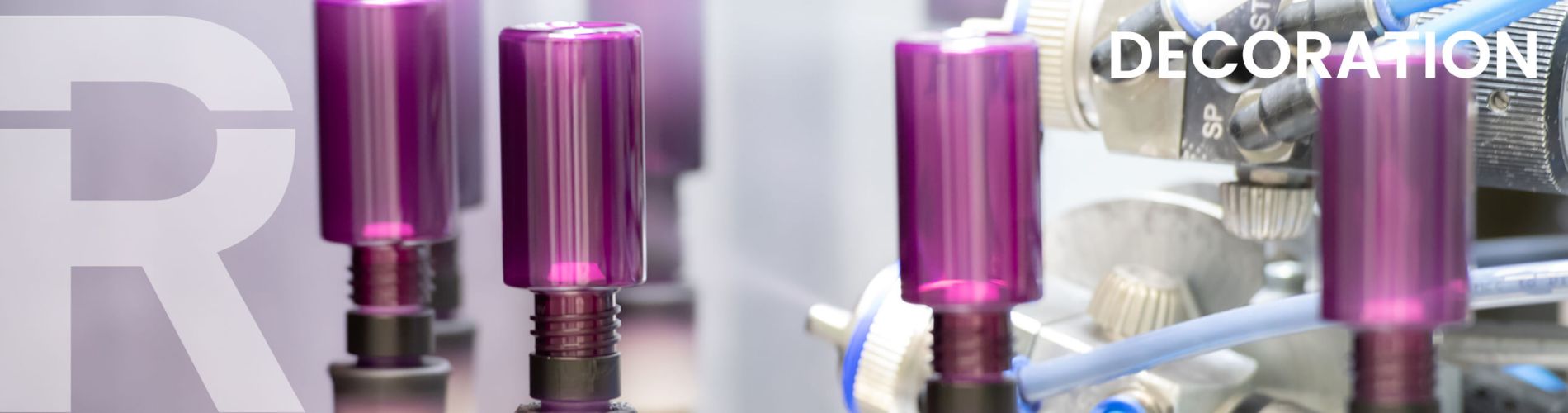

In REBHAN’s decoration department your packaging undergoes

several finishing steps to take it from the basic bottle to the finished product.

Customise your packaging

The various decorative techniques that we can offer inhouse at REBHAN and our many years of experience in screen printing, hot foil stamping, coating and metallisation, leave no (design) wishes to be desired and showcase your brand perfectly! Give free rein to your creativity